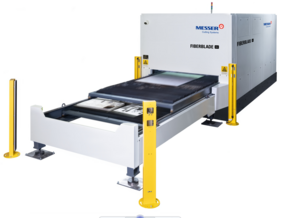

At EuroBlech 2024, Messer Cutting Systems from Groß-Umstadt presented the new FIBERBLADE GU, the ideal entry-level machine for laser cutting. The compact but powerful fiber laser cutting system offers metalworking companies the opportunity to enter the world of laser technology while relying on innovative technology and high efficiency. With its robust design, flexible application options and user-friendly operation, the FIBERBLADE GU is a future-proof solution for the market.

‘With the FIBERBLADE GU, we offer the optimum technology for metalworking companies that want to enter the laser market and are afraid of high investments. It is an economical but powerful solution for precise 2D cutting of standard sheet metal. With three selectable laser powers (12 kW, 20 kW and 30 kW) and four available sizes (3015, 4020, 6025, 8025), the machine adapts to different production requirements,’ says Abraham Balendran, Product Management at Messer Cutting Systems.

Efficient, precise, fast and economical

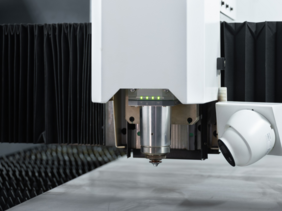

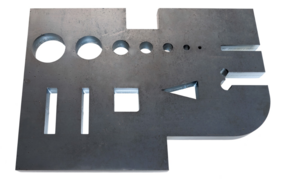

Whether cutting mild steel, stainless steel or aluminium - the FIBERBLADE GU delivers impressive results in every discipline. Depending on the laser power and material, the cutting system cuts material thicknesses of up to 60 mm quickly, precisely and economically. The different models cover cutting ranges from 3,000 x 1,500 mm to 8,000 x 2,500 mm. Proven components such as the Precitec ProCutter 2.0 cutting head ensure precise and reliable performance.

The machine achieves good cutting results not least due to the low-vibration substructure. The solid table construction of the FIBERBLADE GU ensures optimum stability for all material thicknesses. The one-piece aluminium bridge construction gives the FIBERBLADE GU high rigidity combined with low weight. This not only enables dynamic processing, but also significantly increases the cutting performance. The machine works with high acceleration and positioning speed for high efficiency and productivity - even for demanding cutting tasks. The parallel shuttle table also ensures a smooth material changeover, significantly reducing production time.

User friendly and safe

The FIBERBLADE GU combines state-of-the-art laser technology with a user-friendly user interface. The large touchscreen ensures intuitive operation and simple control of the system. The 21.5-inch screen for the four process and room monitoring cameras provides an optimum view of the work area and therefore a perfect overview of the cutting process. Occupational safety during laser cutting is guaranteed by a tested laser enclosure.

Thanks to its full compatibility with the OmniWin software, the FIBERBLADE GU can be seamlessly integrated into existing production processes and offers a flexible solution for modern metalworking companies.

Focus on durability and efficiency

A special feature of the FIBERBLADE GU is its durability and ease of maintenance. Easy access to the components via large inspection hatches makes maintenance work considerably easier. The automatic lubrication of the sliding surfaces keeps the machine ready for use for longer and ensures high performance. In addition, the sectional extraction system on both sides ensures a clean working environment, which further increases the service life and efficiency of the machine.

Abraham Balendran: ‘Minimal cutting costs in the best laser quality make the FIBERBLADE GU an economical and powerful alternative in the compact class. It is therefore the ideal system for companies that want to integrate 2D laser cutting technology into their own workflow.’