Efficiency, reproducibility and process reliability are crucial factors in industrial manufacturing today – especially in thermal applications. With GRIFLAM® heating technology, Messer Cutting Systems offers a modular system for automated heating processes that combines maximum precision with maximum flexibility.

Whether for flame straightening components, automated flame hardening complex workpieces or controlled preheating prior to welding: our GRIFLAM® systems can be integrated into existing production lines – including individually configured torch technology, digital control solutions and process-optimized gas supply.

Your advantages:

• Fully automated flame adjustment for reproducible results

• Energy-efficient torches with precise temperature control

• Compatible with robot, CNC or other carrier systems

• Tailor-made complete solutions from concept to production

Downloads

YOUR ADVANTAGES

Torch systems for every challenge

We have the right torch system for you for applications such as (pre-)heating, cutting, flame straightening or flame hardening. Our experts perfectly tailor the main torch to the desired flame temperature, the effective range and the material to be treated. We also offer a selection of ignition torches that enable automated ignition of the main torch and are monitored by an electrode for your safety. Further options include the installation of a UV probe to monitor the flame on the main torch in order to stop the gas supply in the event of extinguishment. If required, a pyrometer can also be integrated into the system to constantly monitor the temperature of your workpiece and stop the torch when the target temperature is reached or restart it when the temperature falls below the predefined start temperature.

Controls how you envisioned them

Our SIEMENS controllers are adapted to your tasks and you decide which displays should be placed where; even integrating your design is no problem. Our controllers support common industrial protocols such as PROFINET or PROFIBUS for seamless data communication and system integration. Of course, the integrated safety modules ensure compliance with international safety standards and protection against hazards. Our comprehensive diagnostic tools and monitoring functions won't let you down and help with both proactive fault detection and troubleshooting.

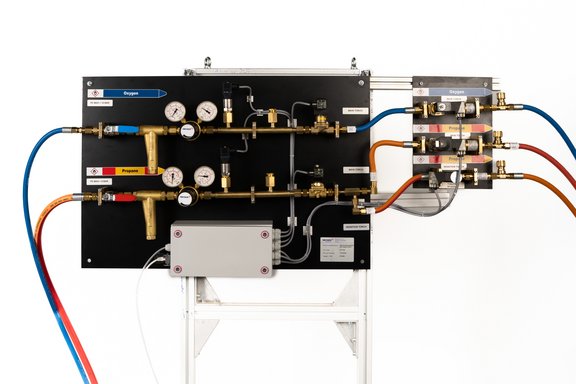

Customized gas supply

We offer our gas supply panels in your desired design – in combination with our torch system, of course, already perfectly tailored to your needs. Integration into existing supplies is possible without any problems. Monitoring systems, alarm and automation functions can also be integrated into your gas supply. The display of live flow rates or live pressures can also be integrated into the control system by installing flow meters and pressure sensors.

Request personal advice

Take advantage of our experts' experience and contact us for a free consultation – we are also happy to visit you on site.

Or use the red enquiry button to send initial information directly to our experts.

We look forward to hearing from you.